Ceramic gyuto? Carbon steel nakiri? What does that even mean!?

So, you want to buy a shiny new Japanese kitchen knife? Well, there's tons to learn, so you'd better buckle up and get ready for a wild ride.

The Intricate World of Japanese Knives Can Be Overwhelming

Japanese knives come in many shapes and sizes: deba, nakiri, and garasuki, to name a few. The most popular ones you might have already heard of are gyuto and santoku.

Yes, I know, there's a lot to think about - your head might have already exploded!

However, knowing the ins and outs of Japanese knives is essential, and once you've decided, the knife you choose can last a lifetime. So, I've created this in-depth guide to help you navigate the rocky world of Japanese knives. Don't worry. I'll turn you into an expert in no time.

Where to Start

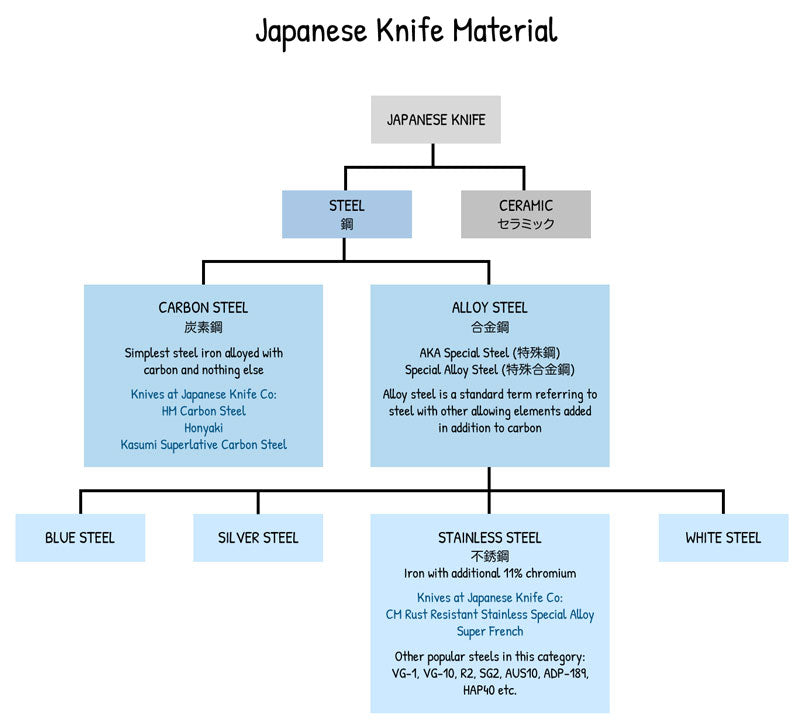

Before you begin even thinking about the shape of the knife that you want, you should be looking at the material that it’s made of because this defines the hardness, sharpness, and care that needs to go into a knife.

The Basics

What are Japanese knives made of?

They're typically made of two types of materials: ceramics or steel. Each with its own pros and cons that I'll go into below. You'll want to know about this because, more than anything, the material will define the feel and longevity of the knife you choose.

Ceramic Knives

Over the last ten years, you may have noticed the appearance of more and more ceramic knives. They're a Japanese invention that's been around since the late 90s. They're not made out of clay like a teacup or a vase. Instead, they're made of shaped and super-heated zirconium dioxide, which creates an incredibly hard blade. Ceramic material is so hard that it's usually sharpened with a diamond grinding wheel. However, you won't need to sharpen this type of knife often. A ceramic blade can retain its sharpness for years before it starts losing its edge. In addition, compared to steel knives, they can be cheaper, and they're far lighter too.

Sounds Great! So, Why Doesn’t Everyone Use Ceramic?

While they may be incredibly hard, they're also paradoxically brittle. Ceramic knives will chip and shatter far easier than steel knives. They're also so light that, for many people, they don't feel as well balanced as a steel knife where the weight has been perfectly distributed. And, although you may not have to sharpen one for years and years, you will need a professional with the right equipment when you do have to sharpen it. Your Japanese waterstones won't help you here; ceramic knives are simply too hard.

Steel Knives

In its most basic form, steel is an alloy made of iron mixed with a small amount of carbon. In this case, the carbon is in the form of charcoal or coal. This small addition makes it significantly harder than iron on its own. You likely already know all about steel. It’s incredibly versatile and can be shaped in any way. It can last for decades without degrading if cared for properly. It’s traditionally what Japanese knives, as we know them today, are made from.

More to Steel Than You Might Expect.

There isn't one single 'steel' used for knife making. For example, there's blue steel, carbon steel, white steel, and stainless steel (which itself has many sub-categories).

All of Them Share Some Similarities.

Unlike ceramics, steel knives are far easier to sharpen at home. They can be very well balanced and come in various natural colors and patterns that ceramics can't match the beauty of. Steel is also far less prone to chipping and is very tough. That's why steel is the most common sort of material that you're going to encounter for Japanese knives.

So, that's all the stuff that's the same, but let's look at the differences between the types of steel you'll most often see used in knives.

The Two Main Categories of Steel

Carbon Steel

This type of steel is composed almost entirely of iron and carbon. Knives made with this steel are very hard and retain a sharp edge for a long time. That means you can have some of the benefits of a ceramic blade and still be able to sharpen your knife at home whenever it begins to dull. Pretty neat, eh?

But, It Comes With the Same Drawbacks.

Although tougher than ceramic, carbon steel knives will still easily chip because they're relatively brittle. They also require much more maintenance as they're not water or acid resistant like stainless steel. That means you need to keep your carbon steel knife dry and oil it after every use or else you risk rusting and corrosion. The good news is that canola or sunflower oil will work just fine. You don't need to buy any special knife oil.

If you treat a carbon steel knife with care and maintain it, you will have an incredibly sharp knife that can last you a lifetime.

Alloy Steel

Alloy steel is carbon steel mixed with various elements such as manganese, nickel, chromium, silicon, tungsten, copper, or boron.

Each of These Elements Gives Steel a Different Property.

Some elements increase hardness, durability, and corrosion resistance and can also change the appearance of the metal. Generally, steel is considered alloy steel when made from 1 - 50% of another element or a mixture of elements. Each blend of alloy steel has unique properties.

Let’s focus first on the most popular one.

Stainless Steel

You would have encountered this steel more than any other. Steel is considered stainless steel when it contains at least 10.5% chromium. That's the element that gives stainless steel its water and corrosion resistance. It's used to make cutlery, tools, parts of buildings, and just about anything else you can think of. And this is for a really good reason. It's incredibly tough, doesn't need as much care as carbon steel, and is far less likely to rust. That's what makes it an excellent material for Japanese knives. You don't have to worry about cutting acidic fruits and vegetables. All you need to do is clean it when you're finished using it. It's also not as brittle as carbon steel or ceramics, meaning it won't chip as easily. But, generally, a stainless steel knife won't be as hard and must be sharpened every month or two if used regularly.

However, Not All Stainless Steel Is Created Equal

Within the umbrella of stainless steel, there are many different types, each with its pros and cons. And, even though some stainless steel knives aren't as hard as carbon steel knives, some are as hard - and even harder! I'll take you through some of the most popular variations of stainless steel used for knives, but there are many more, and innovations are happening all the time.

VG1

Manufacturer: Takefu Special Steel Co., Ltd.

Composition: Carbon (0.95 - 1.05%), Chromium (13 - 15%), Molybdenum (0.2 - 0.4%)

HRC: 61+

You can’t talk about Takefu Special Steel’s V series steel without mentioning the premier product, VG1. It has some of the same properties as the now commonly used VG10. It’s a high-carbon steel made with a mix of chromium and molybdenum.

Is It Worse Than VG10?

You may hear that this steel is lower quality or softer than VG10. The truth is, it's slightly harder steel than VG10 sitting at HRC61, and there's no reason to suspect it's lower quality. The combination of chromium and molybdenum combine to make a firm wear-resistant steel.

Is Harder Better?

But beware, harder isn't always going to be better. VG1 knives will be more brittle and more difficult to sharpen than VG10's complex mix of elements, but this was an impressive start for the V steel series.

These days, you will find fewer knives made from VG1. But, if you find a VG1 knife that you like, it will still be good quality steel, and you may find it at a much lower price than VG10.

|

Pros |

Cons |

|

|

VG2

Manufacturer: Takefu Special Steel Co., Ltd.

Composition: Carbon (0.65%), Chromium (14%), Molybdenum (0.15%)

HRC: 58+

The second iteration in the VG series is significantly softer because of its lower carbon content but is still strengthened with chromium and molybdenum.

The Same Steel?

Not at all! VG2 is a much softer steel than VG1. The manufacturer claims on their website that this aids in the creation of thin blades, which may be true, but more likely, it was created for ease of mass production of knives.

Cheaper Knives

VG2 isn't going to be the go-to steel for professional chefs and knife connoisseurs, but that doesn't mean it's terrible. You will find knives made from this steel far cheaper than other VG Series knives. VG2 can be an excellent choice for a beginner or someone with little money to spend on a knife. You will still get good corrosion-resistant steel that isn't so difficult to sharpen. Just beware; it won't retain its edge for long.

|

Pros |

Cons |

|

|

VG5

Manufacturer: Takefu Special Steel Co., Ltd.

Composition: Carbon (0.75%), Chromium (14%), Molybdenum (0.3%), Vanadium (0.15%)

HRC: 59+

Striking a balance between VG1 and VG2 comes VG5 steel. It has nearly the same makeup as the previous two. However, it sits between the two earlier versions in hardness and wear resistance with the addition of vanadium for a stronger knife edge.

A Balance for Beginners

VG5 steel hits a nice mid-point for beginners who want a relatively hard, decent-quality knife at a reasonable price. It's not as hard or as high-quality as the upper-end steel knives and may well still be mass-produced, but it's hard enough to retain a good edge and has good corrosion resistance.

|

Pros |

Cons |

|

|

VG7

Manufacturer: Takefu Special Steel Co., Ltd.

Composition: Carbon (1%), Chromium (14%), Molybdenum (0.3%), Vanadium (0.15%), Tungsten (1.25%)

HRC: 61.5+

High carbon and the addition of tungsten make VG7 significantly harder than the previous generations of VG Series steel.

Not Just About Hardness

High hardness won't help if it makes a knife too brittle. It's only one of the factors that makes steel suitable for a knife. That's why Takefu Special has added tungsten to make a tougher, more wear-resistant steel. The tungsten balances the high carbon content and makes for very hard and durable knives.

Durability Comes at a Price

VG7, while nowhere near the most expensive of steels, will undoubtedly cost more than knives made with VG1, 2, or 5. But it makes sense, given the expense of adding tungsten for a more durable, stronger steel. Knives made with this steel should retain a good edge and not be too brittle despite being hard.

|

Pros |

Cons |

|

|

VG10

Manufacturer: Takefu Special Steel Co., Ltd.

Composition: Carbon (1%), Chromium (15%), Molybdenum (1%), Vanadium (0.25%), Cobalt (1.55%)

HRC: 60+

VG10 is one of the most popular steels that Takefu Special manufactures for knives. The high carbon, chromium, and cobalt blend make for a hard, durable, and wear-resistant steel. As a result, many knife makers use this steel.

Why So Much Chromium?

You may have noticed that all V Series steels have above-average chromium content. The chromium content is much higher than the 10.5% required for the corrosion resistance of stainless steel. The reason is that chromium counteracts the brittleness that high-carbon content causes when used in higher amounts. It won't necessarily make the blade extra-corrosion resistant, but it will ensure that the knife is less prone to chipping and breakage.

What Does That Mean?

Is it as sharp as a high-quality carbon steel knife? Well, actually, yes, it can be! This steel is designed to be strong in all categories. It can still be as hard as some types of carbon steel but also has good wear and corrosion resistance. In addition, VG10 is designed to be easier to sharpen than other high-carbon steels. With this steel, you get the best of both worlds. But, It isn't cheap. Knives made with VG10 will be priced a little higher than some others.

|

Pros |

Cons |

|

|

VG10W

Manufacturer: Takefu Special Steel Co., Ltd.

Composition: Carbon (1%), Chromium (15%), Molybdenum (1%), Vanadium (0.25%), Tungsten (0.4%), Cobalt (1.55%)

HRC: 61+

Less common than VG10 is this addition from Takefu Special, VG10W. The ‘W’ in this case stands for tungsten, of which a small percentage has been added to make a slightly harder, stronger steel.

Does Tungsten Really Change That Much?

It does, at least, according to the manufacturer. Takefu Special claims that VG10W has “. . .20% higher durability/strength and 25% higher cutting performance. . .” than VG10. As to how they measure this performance, it’s hard to say, but this is a stunning enhancement.

Not Easy to Find

It's unlikely that you'll come across this steel being used in many knives. Its rarity may make it slightly more expensive than VG10, but if what the manufacturer says is true, the extra cost should be worth it if you're looking for something a cut above VG10.

|

Pros |

Cons |

|

|

R2/SG2/SPG2

Manufacturer: Takefu Special Steel Co., Ltd.

Composition: Carbon, Chromium, Molybdenum, Vanadium

HRC: 62+

Confused by the name? You may see knives made with R2, SG2, or SPG2 steel, but these are all the same steel from Takefu Special Steel Co., which knife manufacturers have given different names. Sadly, the exact makeup of the elements used in its creation is kept secret. I can only provide less reliable numbers given by sources outside the manufacturer. Still, it gives us some insight. The carbon content is very high, around 1.25 - 1.45%, and it contains chromium (14 - 16%), vanadium (1.8 - 2.2%), molybdenum (2.3 - 3.3%), and possibly some tiny amounts of manganese and silicon (less than 1% each). R2 is created very differently from Takefu Special's V steel series, as you will see.

What’s So Different About It?

It’s manufactured via powder metallurgy. Essentially, this means that it was first a mixture of various metal powders before being heated and shaped in the factory. That means that R2 steel has a very even distribution of elements giving the material better stability than can be achieved with other methods of steel creation. In addition, the variety of elements makes R2 very wear-resistant and hard steel.

Is It Worth Buying?

R2 is genuinely Japanese super-science, a far cry from traditional steel forging! Therefore, you can expect a high-quality knife made of very stable metal. However, expect to pay a very high price. Of course, the usual downsides apply for very hard steel, but in this case, your budget will determine whether or not this steel is worth it for you.

|

Pros |

Cons |

|

|

AUS-1

Manufacturer: Aichi Steel Corporation.

Composition: Carbon (0.09 - 0.13%), Chromium (12.00 - 13%), Manganese (1%), Molybdenum (0.6%), Nickel (0.6%), Silicon (0.4%)

HRC: 56

The first of the Aichi Steel AUS series, AUS-1, has very low carbon content and a small percentage of additional elements. As a result, it differs significantly from the most recent, AUS-10.

Soft Steel

Despite the above-average chromium and extra elements added, this is a low-carbon stainless steel, more in line with the hardness of European steel.

You Get What You Pay For

First, don't expect to find many knives made of this steel anymore, especially not from any quality Japanese knife manufacturers. Instead, you're more likely to encounter AUS-1 in a supermarket knife. It won't make for a sharp knife and certainly won't hold its edge for long. AUS-1 is a mass-market steel designed to be cheap above all else.

|

Pros |

Cons |

|

|

AUS-4

Manufacturer: Aichi Steel Corporation.

Composition: Carbon (0.4 - 0.45%), Chromium (13.00 - 14.5%), Manganese (1%), Molybdenum (0.6%), Nickel (0.3%), Silicon (0.8%)

HRC: 55-57

AUS-4 is a slight improvement over AUS-1. In this case, it has medium carbon content and a tiny variation in the percentage of other elements used.

A Small Step In The Right Direction

This steel is still, like AUS-1, more similar to a European knife in hardness, but it is a little harder than AUS-1 due to its increased carbon content over its predecessor.

But It’s No Knife for Professionals

Again, like AUS-1, this steel is unlikely to be used in any quality Japanese knives today. It's more often used for pocket knives and hunting knives that need to resist chipping from bone and wood, in which case softer steel can be a good thing. It's not "bad" steel, but it isn't the best if you're looking for a kitchen knife with a long-lasting edge and cutting precision.

|

Pros |

Cons |

|

|

AUS-6M

Manufacturer: Aichi Steel Corporation.

Composition: Carbon (0.55 - 0.65 %), Chromium (13 - 14.5%), Manganese (0.85%), Molybdenum (0.1 - 0.3%), Nickel (0.3%), Silicon (0.8%), Vanadium (0.1 - 0.25%)

HRC: 58

AUS-6M is where the AUS series begins to shine as the quality increases. More carbon than the previous two generations brings this into the high-carbon stainless steel category, where most Japanese steel used in knives tends to be.

Getting Stronger and Harder

It may not be in the top-of-the-line range of Japanese steel, but the higher carbon content and the addition of vanadium to the mixture aid in strength and negate brittleness, making AUS-6M a viable steel for use in Japanese knives.

Respectable Beginnings

You generally won't find professionals using a knife made with AUS-6M, but it's a decent steel for a beginner knife. It's relatively cheap and hard enough to retain its edge after many uses. In addition, an AUS-6M knife will be easy to sharpen and reasonably resistant to chipping.

|

Pros |

Cons |

|

|

AUS-8

Manufacturer: Aichi Steel Corporation.

Composition: Carbon (0.7 - 0.8%), Chromium (13 - 14.5%), Manganese (0.5%), Molybdenum (0.1 - 0.3%), Nickel (0.3%), Silicon (0.8%), Vanadium (0.1 - 0.25%)

HRC: 59

The AUS series steps into the mid-range with AUS-8. This steel slightly ups the carbon content from AUS-6M, but other than the minor decrease in manganese, the rest of the composition remains the same.

Finally, In The Running

Here, the AUS series becomes a more serious contender for quality knife manufacturers. The added hardness from the carbon, wear resistance, and strength gained from the other elements makes AUS-8 more in line with other Japanese quality steels.

Not The Final Generation

This steel is suitable for mid-priced, mid-quality knives. It isn't the best steel, but it isn't the worst. Decent edge retention can be expected from the hardness. Also, expect good corrosion resistance and overall strength too. Is it going to cut as well as carbon steel? Definitely not. But if you buy a knife made from AUS-8, you can expect it to be relatively sharp and good quality for a reasonable price.

|

Pros

|

Cons |

|

|

AUS-10

Manufacturer: Aichi Steel Corporation.

Composition: Carbon (0.95 - 1.10%), Chromium (13 - 14.5%), Manganese (1%), Molybdenum (0.1 - 0.3%), Nickel (0.3%), Silicon (0.8%), Vanadium (0.1 - 0.25%)

HRC: 60

AUS-10 is the latest steel in the AUS series from Aichi Steel. As with others in the AUS line, it’s an elaborate mixture of elements. It’s also one of the most popular of its line and significantly improves upon the previous iterations.

A Complete One-Eighty

AUS-10 is a far cry from the humble beginnings of the AUS-1, which was intended for easy mass production. Instead, Aichi Steel has refined the AUS line, slowly increasing its hardness and quality with each generation.

A Hard Steel But Easy To Maintain Knife

An AUS-10 knife can be a little softer than some high-end knives that can get well beyond HRC 60, but it also comes with many benefits. For one, the added nickel and above-average chromium content give the steel excellent corrosion resistance. Combining these and other elements adds a good amount of hardness, strength, and wear resistance. It also makes for a relatively flexible knife blade, which can prevent damage. A knife made from this material may need to be sharpened a little more often, but the good thing is that it's also much easier to sharpen than a knife made with more rigid steel. Maintaining a knife made from AUS-10 isn't as difficult as some, and you can expect it to take more abuse than others, given its good wear resistance. AUS-10 is at the higher end of mid-range steels.

|

Pros |

Cons |

|

|

ZDP-189

Created By: Hitachi Metals, Ltd.

Manufacturer: Yasugi Specialty Steel (YSS)

Composition: Carbon (3%), Chromium (20%), Manganese, Molybdenum, Silicon, Vanadium, Tungsten

HRC: 65+

The people at Hitachi Metals Co. weren't messing around when they created ZDP-189. This steel is another creation of powder metallurgy, like R2, and it is extremely hard. It has a carbon content of 3% and chromium at 20%, almost double the amount required to be considered stainless steel. According to external sources, it also contains several other elements, as listed above. However, the exact composition is kept secret by Hitachi Metals, so only the carbon and chromium content can be known for sure.

What Do You Get?

Hardest-of-the-hard steel. Where other steel manufacturers boast about their products having around HRC 58 - 62, ZDP-189 sits comfortably near the top with a rating anywhere from HRC65 - 67. That's because of the incredibly high carbon and chromium content. The increased chromium isn't there to make the steel more corrosion-resistant. Instead, it has been added for strength because such a high level of carbon alone would produce very fragile, brittle steel. That, along with tungsten and other elements, hold together to make a tough, incredibly wear-resistant steel.

Why Wouldn’t You Want It?

It may not be the catchiest name, but ZDP-189 is exceptional steel. However, you won't easily find knives made from this powdered steel mixture; if you do, they certainly won't be cheap. Furthermore, once steel starts getting this hard, it becomes tough to sharpen. So, If you buy a ZDP-189 knife, you'll need a lot of patience if you plan to sharpen it at home on some waterstones. You may even need to pay a professional to do it for you. But it'll be a long time before it needs any sharpening.

|

Pros |

Cons |

|

|

SRS-13

Manufacturer: Nachi-Fujikoshi Corporation.

Composition: Carbon, Chromium, Molybdenum, Vanadium, Tungsten, Manganese, Silicon.

HRC: 62-64

SRS-13 is a steel developed by the robotics and machinery company Nachi-Fujikoshi Corporation. While they don't necessarily specialize in steel, they have some steels designed for tools that have made their way into Japanese knives. Unfortunately, the official composition isn't available. However, online sources suggest the following percentages: carbon (1.3%), chromium (13%), molybdenum (2.75%), vanadium(1.5%), tungsten(1.25%), manganese (0.3%) and silicon (0.3%)

What Does This Mixture Do?

As with other powdered steel mixtures, SRS-13 contains various elements to counteract brittleness and increase wear resistance. It's surprisingly hard steel, given that it doesn't have an overabundance of any particular element in its composition. That's due to the high carbon content and its method of production.

Is Powdered Metallurgy Necessary?

It may seem like all this steel metallurgy is overly-complex technology for a kitchen knife. No one could blame you for thinking it's all a marketing gimmick. But, in fact, it's very useful. A homogenous distribution of elements throughout the steel makes it less prone to chipping and easier to sharpen. It's also somewhat easier for knife manufacturers to work with. It is, however, an expensive method of making steel, and SRS-13 knives will reflect that. Unfortunately, you won't be able to buy these knives at a low price. But, if you do buy one, it might be worth it, because SRS-13 knives have very good edge retention and wear resistance.

|

Pros |

Cons |

|

|

SUS420J2

Created By: JFE Steel Corporation

Manufacturer: JFE Steel Corporation (And Others)

Composition: Carbon (0.26 - 0.40%), Chromium (12 – 14%), Nickel (1%), Silicon

(1%), Manganese (1%)

HRC: 52 – 56

JFE Steel Corporation is Japan’s second-largest steel manufacturer, providing steel materials for both infrastructure and tools. However, their business spans the world; therefore, while SUS420J2 is a Japanese innovation, it’s not always produced in Japan. Without extensive testing, it’s difficult to say whether the origin affects quality, but to be safe, opting for SUS420J2 made in Japan is always best.

A Soft Steel With Other Advantages

SUS420J2 is a harder steel than its predecessors (SUS420J1 and SUS410)

because of its slightly increased carbon content. With that said, ranging from HRC

52 – 56, it’s more on par with softer European steel. The higher-than-average

chromium content makes this a very corrosion-resistant steel. Please note that the

nickel content (1%) was only listed in unofficial sources. But nickel would make

sense as an addition to this alloy as it would make it even more corrosion-resistant and prevent damage at higher temperatures, for example, when SUS420J2 is used in machinery or power tools.

Soft Doesn’t Always Mean Bad

Is it atypical for Japanese knives to have soft steel? Frankly, yes. But it means that a knife made from SUS420J2 won’t be prone to chipping, will have good flexibility, and be easy to sharpen. Not to mention SUS420J2 is generally much more affordable than many of the steels on this list and is still of decent quality.

|

Pros |

Cons |

|

|

Other Alloy Steels

Now that you know what ceramics, carbon steel, and stainless steel are, you might wonder what these other non-stainless non-carbon steels are. You could think of these as carbon steels with a twist. Some contain small amounts of various other elements, so they're not technically carbon steel but still require the same amount of care. If you don't want stainless steel and you're looking for something more exotic than regular carbon steel, these are for you.

White Steel

So, if some of these other steels are similar to carbon steel, why were they created in the first place? Well, it's an intriguing story that might change how you think about Japanese steel and the knife you choose.

The Steel of Swords

For hundreds of years, steel called tamahagane was created in Japan using special iron sand (satetsu) harvested from the beaches of the Shimane prefecture. Tamahagane was a very hard steel used for many things in Japan, including tools, knives, and swords, that required expert smithing skills to create and shape. Unfortunately, the mass harvesting of this resource was highly damaging to the environment and has since been stopped, thus ending the legacy of tamahagane. As a result, you are unlikely to come across this steel outside of Japan.

Tamahagane Revived

In 2009 Japanese scientists published a fascinating study. They had teamed up with Hitachi Metals to figure out the exact makeup of a 600-year-old tamahagane sword. They removed a section of the blade and analyzed it. They discovered that the steel contained incredibly low levels of impurities such as sulfur and phosphorus, usually found in iron, which can make steel more fragile.

What Does This Have to Do With White Steel?

In Japan, it’s known as shirogami, meaning white paper. That's because the steel itself isn't white, but it comes wrapped in white paper from the Yasugi Specialty Steel factory in Shimane prefecture (owned by Hitachi Metals, Ltd.). Shirogami is a type of carbon steel made with iron refined to lack impurities, just like traditional tamahagane. This process makes white steel knives sharper and harder than regular carbon steel.

Several iterations of this steel have been created, each slightly different from the last.

White Steel #1

Created By: Hitachi Metals, Ltd.

Manufacturer: Yasugi Specialty Steel (YSS)

Composition: Carbon (1.25 - 1.35%), Silicon (0.1 - 0.2%), Manganese (0.2 - 0.3%)

HRC: 60+

White Steel #1 was the first white paper steel invented by Hitachi Metals and manufactured by Yasugi Specialty Steel. It contains high carbon content with a small amount of silicon and manganese to aid strength and toughness.

How Is It Different From Regular Carbon Steel?

The high carbon content and low presence of impurities make it harder than typical carbon steel with an HRC of at least 60. White Steel #1 knives can be sharpened to an exceptionally sharp edge.

A High Price For Skilled Work

Knives made from this steel are much rarer and more expensive than other types of knives, and for a good reason. White steel, particularly the brittle white steel #1, is exceedingly tricky for blacksmiths to work with. It can easily crack and break during the forging process. But the good thing is you can feel safe knowing that only the most expert blacksmiths can create a knife using this material. Hence, it guarantees that a knife made with this material will be at the utmost levels of craftsmanship.

|

Pros |

Cons |

|

|

White Steel #2

Created By: Hitachi Metals, Ltd.

Manufacturer: Yasugi Specialty Steel (YSS)

Composition: Carbon (1.05 - 1.15%), Silicon (0.1 - 0.2%), Manganese (0.2 - 0.3%)

HRC: 60+

The second version of white steel has less carbon but the same amount of silicon and manganese as white steel #1.

A Little Softer

White steel #2 is still very hard steel, and with less carbon content, it will be less brittle than white steel #1. However, it won't take as sharp an edge because it isn't as hard. It still has an HRC of at least 60 but not nearly reaching the heights of the original white steel. White steel #2 knives can be slightly more affordable than white steel #1, but they're not cheap.

|

Pros |

Cons |

|

|

White Steel #3

Created By: Hitachi Metals, Ltd.

Manufacturer: Yasugi Specialty Steel (YSS)

Composition: Carbon (0.8 - 0.9%), Silicon (0.1 - 0.2%), Manganese (0.2 - 0.3%)

HRC: 60+

The third version of this steel is the same combination again but with even less carbon than white steel #1 and #2.

It’s A Matter of Preference

White steel #3, as you might suspect, is softer still than the previous two versions. Again, this is to mitigate the brittleness of high carbon content, but it still won't be nearly as tough as some alloy steels. It can still be sharpened to a fine edge but won't retain it for as long as white steel #1 or #2 due to its slight decrease in hardness.

|

Pros |

Cons |

|

|

Who Is White Steel Good For?

Many chefs like white steel for its fantastic cutting ability and outstanding edge retention. Although each version is slightly different, they are all excellent quality steel. Anyone who wants a top-of-the-line Japanese carbon steel knife, and has no problem paying a high price for master craftsmanship, should seek out a knife made from white steel.

White Steel Stays Shiny Forever, Right?

Unfortunately, even if you take the utmost care with your white steel knife, it will still develop a natural patina on the surface over time as you use it. That isn't necessarily bad, as it doesn't affect a knife's performance. Think of it as the natural beauty of the steel. Your carbon steel knives will never look the same as another knife. They change over time in the same way that leather does. But it does mean you must be wary of water and acid touching your knife. The last thing you want is rust on your expensive white steel knife. It's no more resistant to corrosion than any other carbon steel.

Blue Steel

Blue steel, also known as aogami (blue paper), is an alloy steel created by Hitachi Metals. It's made with a base of white steel and then has more elements added to it to decrease the brittleness of the steel and make it easier for knife manufacturers to work with. It comes in three types: Blue Steel #1, #2, and Super Blue Steel.

Blue Steel #1

Created By: Hitachi Metals, Ltd.

Manufacturer: Yasugi Specialty Steel (YSS)

Composition: Carbon (1.25 - 1.35%), Silicon (0.1-0.2%), Manganese (0.2 - 0.3%), Chromium (0.3 - 0.5%), Tungsten (1.5 - 2%).

HRC: 60+

You'll notice that this steel has many more elements added than white steel, but you may also see it has the same carbon content range as White Steel #1. Of course, that's because white steel is the base that makes up blue steel.

Why Add More Into The Mix?

Blue steel was designed to retain an edge for longer than white steel and to better resist chipping and other damage. It's still about as hard as white steel, but the mixture of tungsten, chromium, and silicon makes blue steel more resistant to wear and less brittle. Don't be fooled by the chromium, however. This steel is no more corrosion-resistant than white steel, so you'll still have to take good care of it.

|

Pros |

Cons |

|

|

Blue Steel #2

Created By: Hitachi Metals, Ltd.

Manufacturer: Yasugi Specialty Steel (YSS)

Composition: Carbon (1.05 - 1.15%), Silicon (0.1 - 0.2%), Manganese (0.2 - 0.3%), Chromium (0.2 - 0.5%), Tungsten (1 - 1.5%).

HRC: 60+

From the name, it won't surprise you to find out that this is made from a base of White Steel #2. It is the second iteration of Hitachi Metal's blue steel series.

Any Difference From Blue Steel #1?

Just like its White Steel #2 origins, Blue Steel #2 is formulated to be less brittle at the expense of some hardness. As a result, this steel is slightly easier to sharpen than Blue Steel #1.

|

Pros |

Cons |

|

|

Super Blue Steel

Created By: Hitachi Metals, Ltd.

Manufacturer: Yasugi Specialty Steel (YSS)

Composition: Carbon (1.4 - 1.5%), Silicon (0.1 - 0.2%), Manganese (0.2 - 0.3%), Chromium (0.3-0.5%), Tungsten (2 - 2.5%), Vanadium (0.3 - 0.5%).

HRC: 60+

Also known as Aogami Super, Super Blue Steel is the pinnacle of the blue steel series from Hitachi Metals. In this case, they've added much more tungsten than the previous two iterations and even a small amount of vanadium.

Why Is It The Pinnacle of Blue Steel?

Along with higher carbon content, the tungsten and vanadium can create a very strong, wear-resistant blade that is still super hard with a fine cutting edge. It's everything that the blue steel series set out to achieve.

Premium Carbon Steel

None of these steels will come cheap, not only because of the expensive elements used to create the steel but because of the difficulty in forging a knife made from it. However, if you want a sharp, long-lasting knife edge and have plenty to spend on your knife budget, then any knives made from white or blue series steels from Hitachi Metal will serve you well. But remember, these require care and will be particularly difficult to sharpen because of their hardness.

|

Pros |

Cons |

|

|

Yellow Steel #2

Created By: Hitachi Metals, Ltd.

Manufacturer: Yasugi Specialty Steel (YSS)

Composition: Carbon (1.05 - 1.15%), Silicon (0.1 - 0.2%), Manganese (0.2 - 0.3%)

HRC: 58-60

Yellow steel, also known as kigami for the yellow paper it comes wrapped in, is the origin of white and blue steel. Hence, it has a lot in common with them, and, although slightly less popular, is still an excellent carbon steel.

The Predecessor to White Steel

If you're especially sharp-eyed, you may have noticed that this steel has the same composition as White Steel #2. That's because the only difference is in the percentage of impurities:

Yellow Steel #2: phosphorus (0.03%), sulfur (0.006%).

White Steel #2: phosphorus (0.025%), sulfur(0.004%).

Seems hardly different at all. So, what’s the deal?

Yellow Steel #2 knives are typically a little cheaper than Blue or White Steel knives. They're still just about as hard and can get to a fine edge, but that additional amount of impurities makes it more brittle and less wear-resistant than White Steel #2. Having said that, if you find that a reputable knife manufacturer has made a knife using Yellow Steel, it should still be of very high quality. Further, most inexperienced knife users will generally be unable to tell the difference between a Yellow Steel knife and a White Steel knife if they are both made to a high standard.

|

Pros |

Cons |

|

|

HAP10

Created By: Hitachi Metals, Ltd.

Manufacturer: Yasugi Specialty Steel (YSS)

Composition: Carbon (1.3 - 1.4%), Chromium (4.5 - 5.5%), Molybdenum(5.5 - 6.5%), Vanadium (3.6 - 4%), Tungsten (2.5 - 3.5%)

HRC: 58+

Another powdered steel mixture from Hitachi Metals is the HAP10. This steel has an intriguing combination of carbon, molybdenum, tungsten, and vanadium. A vast range of elements in large amounts compared to many other types of carbon/alloy steel.

Not Designed For Knives

This steel is mainly used in high-speed tools, meaning drills and saws. That's why it contains so much molybdenum, which helps steel retain its strength even at hot temperatures. As you may imagine, this is useful when drilling through wood or other metals when there's a concern that friction will create too much heat and damage the steel.

But If It Was...

So, why does this steel need to be mentioned at all with regard to knives? While it isn't very often used in quality Japanese knife making, it still bears mentioning because the later additions of the HAP series are often used in knives (and tools). And, although you're unlikely to find HAP10 being used in knives, it doesn't mean that it would make for a bad knife. Indeed, if it can cut through hard materials, it can cut through meat, fruit, and vegetables. But note that this, and all others in the HAP series, are semi-stainless steels and will therefore need a moderate amount of care. They don’t contain the required 10.5% chromium to be true stainless steel.

|

Pros |

Cons |

|

|

HAP40

Created By: Hitachi Metals, Ltd.

Manufacturer: Yasugi Specialty Steel (YSS)

Composition: Carbon (1.27 - 1.37%), Chromium (3.7 - 4.7%), Molybdenum(4.6 - 5.4%), Vanadium (2.8 - 3.3%), Tungsten (5.6 - 6.4%), Cobalt (7.5 - 8.5%)

HRC: 64 - 68

Similarly to HAP10, HAP40 is designed for high-speed tools. Other than slight differences in the ratios of elements, the significant addition is cobalt.

After All, A Knife Is A Tool

Remember how I said HAP10 was mainly used for tools such as saws and drills? It's the same for HAP40, except it is also used for Japanese knife manufacturing. It's likely because it is made significantly harder with the addition of cobalt, which enhances the effects of the other elements, especially molybdenum. That gives HAP40 a harder edge that's good for fine cutting.

Why Not Just Choose Carbon Steel?

HAP40 may not be highly corrosion resistant, but it is super-hard, harder than many carbon steel knives, with an HRC maximum of 68. It's very wear-resistant, but it won't be easy to sharpen. Still, so long as you keep it clean and oil it, you'll have a razor-sharp knife that retains its edge after many uses. You will find this steel in higher-end knives at a high price.

|

Pros |

Cons |

|

|

Titanium Knives

Not every knife is made from ceramic or a type of steel. One alternative material is titanium. Titanium isn't a traditional metal for knife making, but depending on your needs, it could be what you're looking for. It comes in either a pure metal form or as an alloy containing elements like molybdenum and vanadium to counteract some of titanium's brittleness. Titanium is used to make knives that usually fall under three categories, each with advantages and disadvantages.

Solid titanium knives are the least common that you'll come across. That's because, on its own, titanium is brittle - even more so than many types of hard steel. However, a full titanium knife will be incredibly lightweight and have extraordinary corrosion resistance, even compared to stainless steel. But, because of its fragility and less than super-fine edge, you'll not often find a Japanese manufacturer using this material on its own. Instead, you're more likely to see titanium in this form used for survival knives where weight is an important consideration.

These knives are steel-core knives coated in titanium for extra corrosion resistance. This sort of construction can be beneficial if your main concern is corrosion. For example, if you're planning on cutting a lot of acidic fruits or if the knife needs to be used underwater. But again, don't expect a titanium coated knife to have good edge retention or top-level cutting ability. The steel core, however, will strengthen the knife against breakage.

Here, the opposite of titanium coating is true. The core is titanium, and the coating is steel. That grants the lightness of titanium without losing the fine edge of steel. As a result, these knives are great for consumers who prefer something lighter. Also, because of the reduced weight, people with health issues and wrist problems can benefit from titanium knives. However, you will still want to make sure that the steel coating is the steel you prefer.

Is Titanium Good For Me?

As you can see, it's very specific to your needs. The vast majority of professional chefs won't choose a titanium knife. That's because they tend to be brittle, not especially sharp, have poor edge retention, and are more difficult to sharpen than steel. For these types of knives, it's going to be all about the specific reason you need one. If you need something particularly lightweight or corrosion-resistant, titanium is a fantastic material. However, don't expect to find a titanium knife that comes close to a quality steel knife.

Japanese Knife Co. Steels

The knives that we offer are made with specifically formulated proprietary steels. You will not find them listed anywhere else outside of Japan, nor will you find an exact compositional breakdown. They are each designed for specific users regarding budget, maintenance requirements, and expertise. The artisans who make our knives know these materials intimately and have chosen or created them with high purity and reliability in mind. We offer multiple stainless steel and carbon steel options.

Super French

Type: Stainless Steel

Super French is an ode to the history of Western-Japanese fusion. That's why you'll find it being offered as an option in our Gyuto and Petty knives, designs first inspired by the French Chef's knife and Paring knife over a hundred years ago. It is a highly corrosion-resistant, low-maintenance stainless steel. Super French is intended to be a budget-friendly, no-fuss option for home cooks and beginners. But don't let that fool you - It has exceptional sharpness and edge retention that you'll struggle to match elsewhere in its price range.

|

Pros |

Cons |

|

|

Super French Knives: Petty, Gyuto

CM Stainless

Type: Stainless Steel

The CM in CM Stainless stands for 'Chromium' and 'Molybdenum,' the two prominent elements which lend strength and stability to its high-carbon content. It is intended to punch above its weight with both the easy-to-maintain corrosion resistance of stainless steel and the extreme hardness of carbon steel. This perfect balance makes it one of our most popular options for professionals and home cooks.

|

Pros |

Cons |

|

|

CM Stainless Knives: Petty, Gyuto, Santoku, Nakiri, Deba, Yanagiba

Kasumi Superlative Carbon Steel

Type: Carbon Steel

Kasumi, meaning 'mist,' isn't so much a type of steel as an art form and uniquely Japanese technique. The idea is that soft steel supports harder high-carbon steel to prevent chipping and breakage. Using this technique allows the knife makers to utilize extra-hard carbon steels that, while incredibly sharp, would be too brittle. The result is a beautiful 'mist' line across the blade where the two different steels meet. This two-steel marriage is deadly sharp. However, it still requires oiling and care like any other carbon steel.

|

Pros |

Cons |

|

|

Kasumi Knives: Nakiri, Deba, Yanagiba

HM Carbon Steel

Type: Carbon Steel

HM Carbon Steel is a traditional, handmade steel containing only carbon and the best Japanese iron with minimal impurities such as sulfur and phosphorus that weaken steel. It's the most classic type of steel we have available and the one that Japanese chefs most often prefer. It's the definition of Japanese knife artistry: precision cutting and incredible edge retention.

|

Pros |

Cons |

|

|

HM Carbon Steel Knives: Petty, Gyuto,

Honyaki

Type: Carbon

Like Kasumi, Honyaki is not a steel type but a complicated method of steel forging that only masters dare attempt. Typically, it is done with the highest-quality carbon steel, such as white steel. The idea is that by carefully covering the upper half of the blade with clay before quenching, the steel along the blade's edge hardens, but the rest remains soft and sturdy along the spine. Effectively, it's making a Kasumi blade but with only a single piece of steel. However, the process is complex and can crack the steel if done incorrectly. Hence, only the most experienced smiths attempt it, ensuring the resulting knife is among the best available.

|

Pros |

Cons |

|

|

Get Free Bonus Books

Sign up for free to the Japanese Knife Club to get advice and exclusive articles about how to choose Japanese Knives, and tips and tricks for using Japanese knives.

About the author

Kei Nishida

Author, CEO Dream of Japan

Certification: PMP, BS in Computer Science

Education: Western Washington University

Kei Nishida is a passionate advocate of Japanese craftsmanship, a writer, and the founder and CEO of Japanese Knife Co., Japanese Green Tea Co., and Japanese Coffee Co., all part of Dream of Japan.

His journey began with a mission to introduce the world to the exquisite flavors of Japanese green tea. Through Japanese Green Tea Co., he pioneered the import of premium tea grown in nutrient-rich sugarcane soil, earning multiple Global Tea Champion awards. He then expanded into the world of coffee, launching Japanese Coffee Co., the first company to bring Sumiyaki charcoal-roasted coffee to a global audience.

With a deep appreciation for Japanese artistry and tradition, Kei turned his attention to one of Japan’s most revered crafts: bladesmithing. Through Japanese Knife Co., he made handcrafted katana-style knives, created by a renowned katana maker, available outside Japan for the first time. These exceptional knives embody centuries of samurai sword-making expertise, blending tradition with modern functionality for chefs and collectors alike.

Kei’s journey continues as he uncovers and shares Japan’s hidden treasures—one sip, one blade, and one legacy at a time.