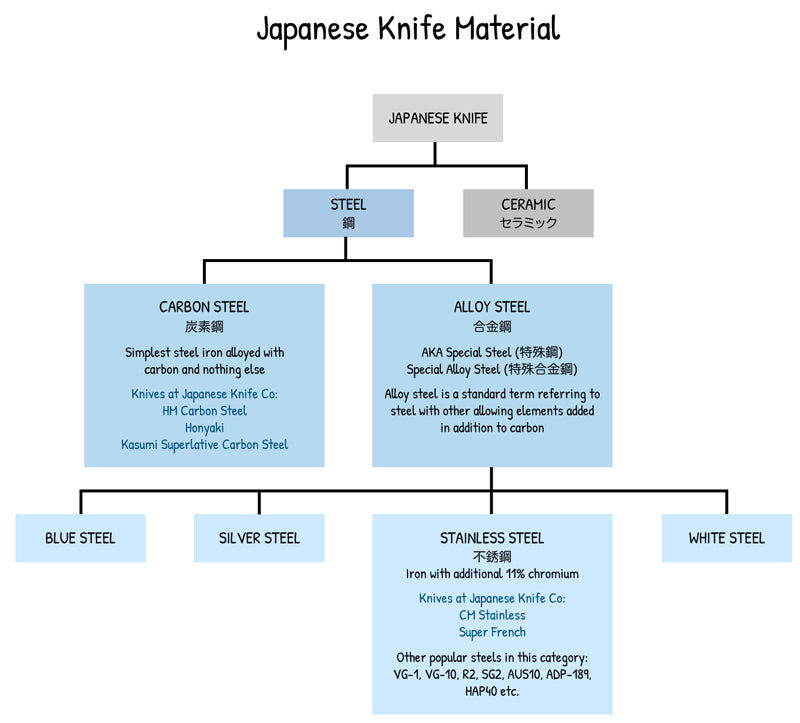

Carbon steel contains carbon as its primary alloying element, typically 0.12% to 2.0% carbon content by weight. The term "carbon steel" is used to distinguish it from alloy steels, which contain other elements besides carbon.

Carbon steel is popular for many industrial applications due to its strength, durability, and affordability. It is commonly used in construction, machinery, tools, and transportation equipment. It can also be easily shaped and welded, making it versatile for various manufacturing processes.

The properties of carbon steel can be modified by varying the amount of carbon and other alloying elements. Carbon steel with higher carbon content is generally stronger and harder, but also more brittle and less ductile—lower carbon content results in a material that is more malleable and easier to work with. The addition of other alloying elements, such as manganese, silicon, and copper, can further enhance the properties of carbon steel.

Are there low and high-carbon steel knives?

Yes, there are both low and high-carbon steel knives. The amount of carbon in the steel affects its hardness, strength, and durability. Different carbon content levels can result in knives with different properties and performance.

Low-carbon steel (also known as mild steel) typically contains between 0.05% and 0.30% carbon, and it is generally softer and more ductile than high-carbon steel. As a result, knives made from low-carbon steel can be easier to sharpen and maintain, but they may not hold an edge as well and may not be as strong as high-carbon steel knives.

On the other hand, high-carbon steel contains between 0.6% and 1.5% carbon, which is generally harder and stronger than low carbon steel. As a result, knives made from high-carbon steel can hold a sharper edge and are generally more durable, but they can also be more brittle and more difficult to sharpen.

In addition to low and high-carbon steel, intermediate carbon steels contain between 0.3% and 0.6% carbon. These steels offer a balance between the strength and durability of high-carbon steel and the flexibility and ease of use of low-carbon steel.

Ultimately, the choice between low and high-carbon steel knives depends on the specific needs and preferences of the user. Professional chefs and home cooks may choose different types of knives depending on the tasks they need to perform and their personal preferences for sharpening and maintenance.

Are Japanese knives made of high-carbon steel?

Traditional Japanese knives are made from high-carbon steel, known for its ability to hold a sharp edge and maintain its hardness. In fact, high-carbon steel is a common material used in many high-end Japanese knives.

The specific type of steel used in Japanese knives can vary depending on the maker and the intended use of the knife. For example, some Japanese knives are made from a type of steel called "hagane," known for its superior hardness and sharpness. Other knives may be made from a combination of different types of steel, or may use a layered construction technique that combines high-carbon steel with other materials.

High carbon steel is favored in many traditional Japanese knife-making techniques because of its ability to be forged and heat-treated to create a very sharp and durable edge. However, high-carbon steel does require more maintenance than other materials, as it is more prone to rust and discoloration. This is why many Japanese knife makers use a particular type of carbon steel that is more resistant to corrosion and staining.

Overall, Japanese knives are known for their exceptional sharpness and precision, and high-carbon steel is often a key factor in achieving these qualities.

1. Sharpness:

High-carbon steel can achieve and maintain a very sharp edge. Japanese knives are often ground to a very acute angle, allowing for precise cutting.

2. Hardness:

Carbon steel can be heat-treated to achieve a high hardness level, allowing for a sharper and more durable edge.

3. Tradition:

Japanese knife-making has a long tradition of using carbon steel. Master Japanese knife makers often use traditional techniques, and these techniques typically involve the use of high-carbon steel.

However, there are some downsides to using carbon steel. It is more prone to rust and discoloration than stainless steel, requiring more maintenance and care to keep it in good condition. Additionally, it can be more brittle and prone to chipping, so it requires more care and skill to use properly. Despite these challenges, many professional chefs and home cooks prefer the superior sharpness and performance of Japanese knives made from high-carbon steel.

Get Free Bonus Books

Sign up for free to the Japanese Knife Club to get advice and exclusive articles about how to choose Japanese Knives, and tips and tricks for using Japanese knives.

About the author

Kei Nishida

Author, CEO Dream of Japan

Certification: PMP, BS in Computer Science

Education: Western Washington University

Kei Nishida is a passionate advocate of Japanese craftsmanship, a writer, and the founder and CEO of Japanese Knife Co., Japanese Green Tea Co., and Japanese Coffee Co., all part of Dream of Japan.

His journey began with a mission to introduce the world to the exquisite flavors of Japanese green tea. Through Japanese Green Tea Co., he pioneered the import of premium tea grown in nutrient-rich sugarcane soil, earning multiple Global Tea Champion awards. He then expanded into the world of coffee, launching Japanese Coffee Co., the first company to bring Sumiyaki charcoal-roasted coffee to a global audience.

With a deep appreciation for Japanese artistry and tradition, Kei turned his attention to one of Japan’s most revered crafts: bladesmithing. Through Japanese Knife Co., he made handcrafted katana-style knives, created by a renowned katana maker, available outside Japan for the first time. These exceptional knives embody centuries of samurai sword-making expertise, blending tradition with modern functionality for chefs and collectors alike.

Kei’s journey continues as he uncovers and shares Japan’s hidden treasures—one sip, one blade, and one legacy at a time.